In September 2014, a chemistry teacher from a Colorado high school was demonstrating a spectrum of bright lines with a large flame for the class. The multi-colored flames generated a so-called rainbow effect, that would certainly impress the students. Unfortunately, while this demonstration was happening, four students were injured. All four of them suffered burns and one became serious.

Could this tragic accident have been prevented? Do teachers and students need to follow safety instructions before conducting experiments? Where can they find the information to use chemicals in a safe manner? Yes, there are sources providing easily accessible information in these areas. These documents are commonly known as Safety Data Sheet (SDS), containing a wealth of information in a simple, easy-to-read format. Every chemical has its own SDS and especially prominent within each SDS are safety precautions required to manage the chemical in a safe mode.

Humans are surrounded by many substances in their daily lives which are not completely safe. Humans use pesticides, herbicides, paints, detergents, shampoos, and many other products that contain various synthetic chemicals. Some of those chemicals are perfectly safe, while others may or may not be safe, or have known risks. However, just because something isn’t safe in the long term doesn’t mean that it’s illegal. Very often, these substances are allowed for use, because the risks are still fairly low, if used in moderation. But what is important is the knowledge of the underlying risks.

May studies highlight that babies and toddlers should be free to play with sand, as the activity adds immeasurably to their learning and enjoyment. But SDS related to ‘sand’ indicates that majority of sand originates from quarried quartz rocks and contains crystalline silica, a carcinogen. In addition to the cancer risk, sand particles can be a risk to children’s developing lungs. Also, we may not realize that sand, in its commonly encountered forms, is not easy to inhale. This is how SDS helps us.

SDS is a common resource used by industries/businesses to inform consumers and workers of the underlying risks from substances. These documents provide workers with procedures for working with or safely handling a particular substance. They also include instructions regarding necessary protective equipment to be used, handling spills, first aid suggestions, storage and disposal, and general health effects.

RMSI, a technology provider offers conversion services in the safety domain to various industries. We maintain our client’s SDS management system by updating product and safety information, while following specific rules and guidelines set by individual manufacturers. A case in point is a unique project that is nearly two decades old, where our experts have been extending conversion services for millions of safety data sheets (SDS) for one of the world’s largest chemical management solution providing company.

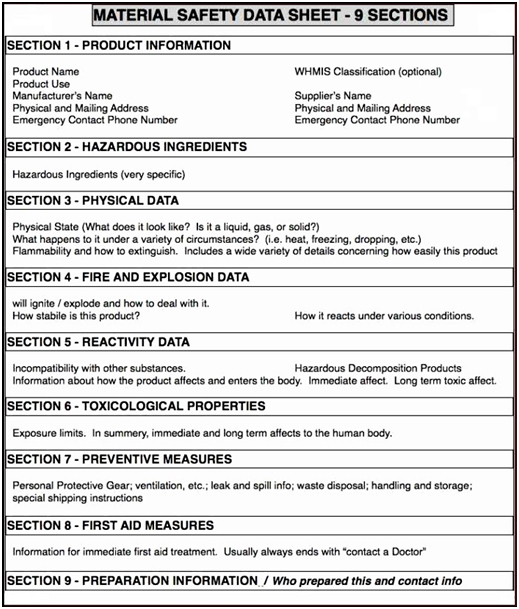

Safety Data Sheet – Content

Language used for the SDS content should be simple and precise, avoiding jargons, acronyms and abbreviations. Misleading expressions should be completely avoided. The information available on the SDS has to be very clear as it is crucial to both the buyer and the supplier.

A safety data sheet must contain at least nine categories or sections of content. SDS should be reviewed atleast once in every three years. The categories should cover the following areas:

-

- Product Information:

- Hazardous Ingredients:

- Physical Data:

- Fire and Explosion Hazard:

- Reactivity Data:

- Toxicology Properties:

- Preventative Measures:

- First Aid Measures:

- Preparation Information:

Most organizations prefer to manage their safety data sheets electronically, promoting their business and growth by saving time, money, improving efficiencies, reducing risk, and enabling sustainability. It is important to ensure that SDSs are readily available and accessible in the workplace, so that they can be easily located in an emergency, such as fire or at an instance where a potential or existing purchaser makes a request for an SDS. The information in SDSs must always be kept updated. This is enforced in various ways. For example, in Alberta, Canada, an employer who does not have the required SDS available can be issued an on-the-spot $500 fine. However, the requirements and enforcement vary between countries and provinces.

Most countries have regulations that require the SDS to be in native language(s) of that country. So an SDS in the USA or UK must be in English, one in Norway must be in Norwegian, an SDS in Canada must be available in both English and French etc. In general, it is the manufacturer or distributor who is responsible for creating the sheet.

The importance and sensitivity of the SDS cannot be overstated. The potential for harm is very real if people do not understand how to handle an accident involving chemicals. As a consequence, the SDS must be treated with the same importance and sensitivity.

Protect your people and organization with the help of SDS.